PLEASE NOTE: As of June 2021 we stopped taking on any new bespoke orders due to needing to catch up on the existing workload. In 2024 we decided we wouldn't be going back to it as we remained too busy. We apologise for any inconvenience.

Please note however, we take on mild custom fit work based on what people are able to try on in the shop (not with measurements). As an example: someone who might fit our size 9 for length, may prefer the width and or instep of the 9.5, or 10. This is a modification we can do, but to a point, depending also on the style and pattern. Split sizing, alterations to lasts and patterns will incur extra charges starting from $100 for a split size, up to $200-$600 on average for customised fits.

Below is the older Bespoke information we used to note for potential customers. As alternatives we can recommend the following:

James B.Young in N.T

Josef Selway in Qld

Eugenia Neave in S.A

Andrew McDonald in NSW

Brendan Dwyer in VIC

There are two main ways you can order footwear through Wootten. Lots of people like to come into the Ballarat store and have a look around or take a squiz at our website range and choose a model that suits them. Once you’ve found a shoe you think suits you down to the ground, the individualisation starts. We call this our Standard or Made-To-Order service. This takes place at our Ballarat flagship store where all our fitting stock is located.

If you can’t find a shoe that’s quite the right fit, or you’ve got an idea of your own that you want to turn into a glorious cordwained reality, our Custom Fit/Bespoke service might be for you. See below.

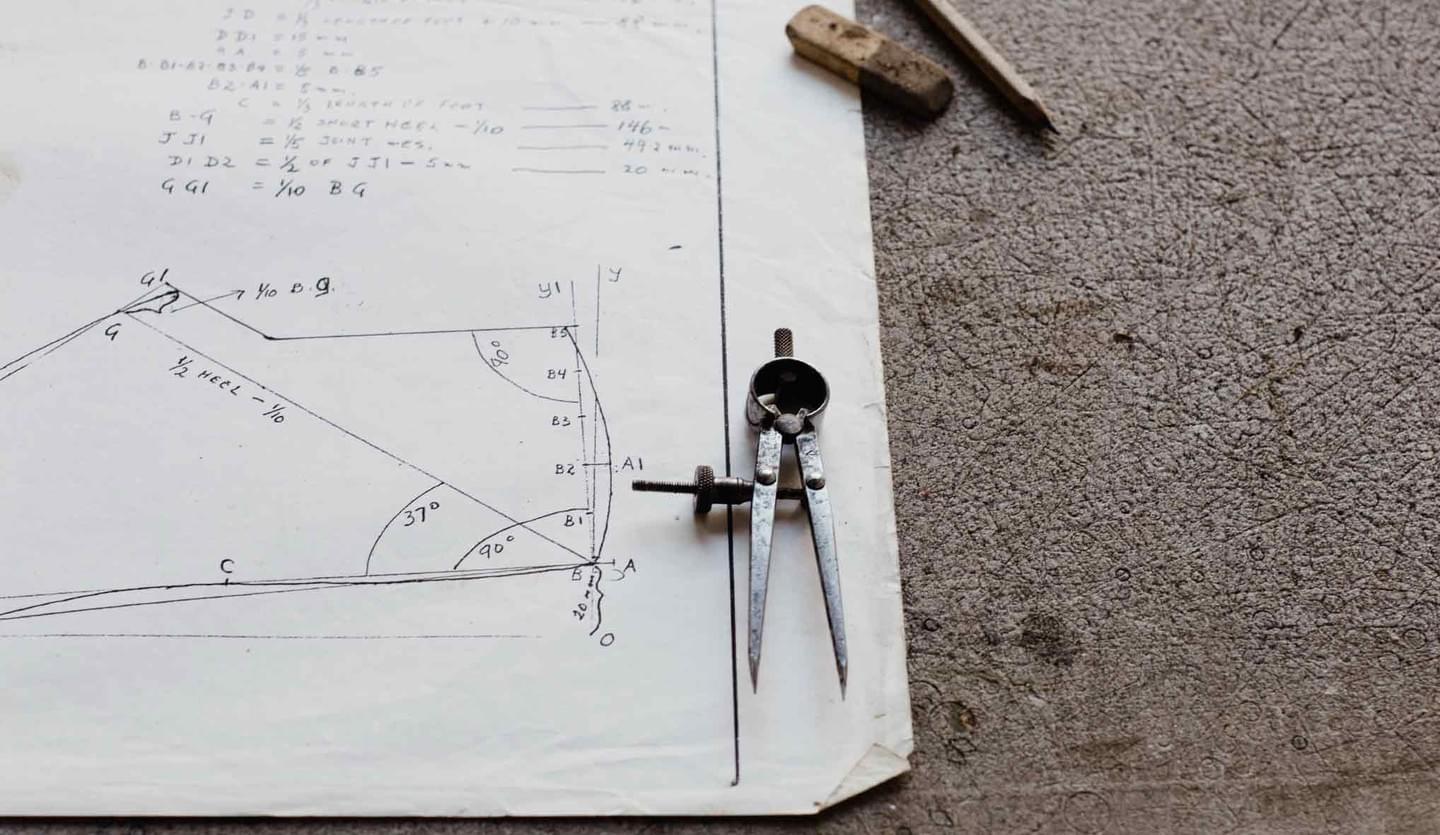

What do we mean by Custom Fit?

This footwear is made using our standard designs and then making adjustments to tailor the fit to your foot requirements and measurements.

What do we mean by Bespoke?

Bespoke is a concept that lies at the heart of slow fashion; it’s the diametric opposite of mass production. If you go to the dictionary you’ll find that it simply means “specially made” and “arranged in advance”. We think it’s a bit more interesting than that. In fact, we think it involves a touch of magic — and that’s even before the cordwainers get crafting. As soon as you step into the shop with bespoke shoes on your mind, a metamorphosis takes place: you transform from humble customer into creative customiser. (One guy reckons he even heard a harp sound when he crossed the threshold, but he’d had a couple.)

Of course, you’ll have the expert guidance and advice of head cordwainer, Jess, and oxblood-colour aficionado, Krys, at your disposal every step of the way, but when you choose the Wootten bespoke service, you choose to play a crucial role in the creation of your own delightful piece of footwear.

Considerations: By appointment only at our Ballarat workshop. This service is currently on hold.

As a requirement, all clientele need to meet with Jess to be measured at the Ballarat store for their one-on-one consultation with the cordwainer as well as for their follow up fitting(s) many months later. Bespoke shoes are on average between $1500- $1800 for your first pair. More complex fits and orthotics can push this higher. Bespoke ankle boots can be more depending on the height and style. Knee high boots typically fall between $1800-2200+, but will vary depending on leather chosen, construction detail and complexity of fit, which may push this higher. More orthopaedic footwear needs can push these price ranges higher for custom orthotics, build ups, etc.

Timeframes for bespoke footwear are currently up to 12 months from receiving the deposit, but will vary with the level of work that comes in and how busy we get. You will typically see us for your first fitting between 5-8 months after the 50% deposit has been paid. Once the fit is confirmed by the customer, soling proceeds and takes approximately 4-8 weeks to completion.

See also:

Please note that our custom/bespoke footwear orders are by appointment only at our Ballarat workshop. Please feel free to contact us or use the form to schedule an appointment.